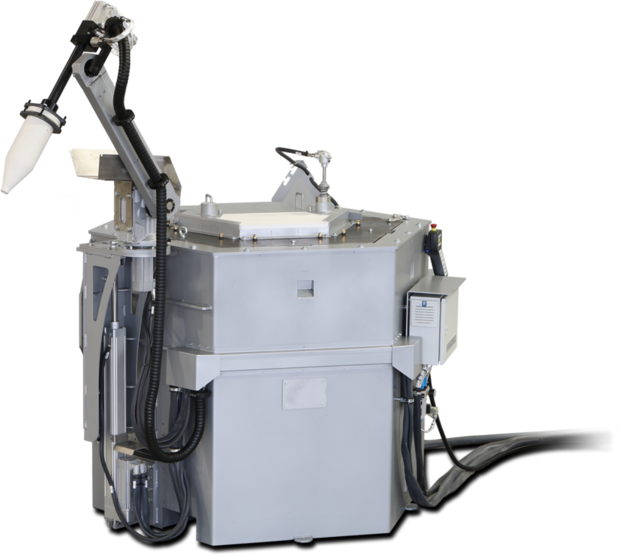

AVDF-CM

Aluminium Vacuum Melting- and und Dosing Furnace

The crucible furnaces are designed for the melting and holding of aluminum die-cast alloys. The high-quality insulation leads to very low energy consumption and thus low operating costs. The easy handling of the insulated cover provides very good access to the crucible and low effort for melt cleaning. Standardized graphite crucibles are used in the furnaces, which allow the aluminum alloy to be melted indirectly. The heating is provided by the heating bands integrated in the furnace chamber, which are characterized by their high performance and durability. Changing the heaters can be carried out without any problems. The heating bands are controlled via thyristors, which keep the melt at the right temperature without overheating.

By installing an impeller, the melt can be flushed with flushing gases and degassed for melt treatment. Thus, the density index is improved again.

The dosing system consists of a vacuum ceramic container, an evacuation device for sucking in the melt and a special closure at the suction point. The vacuum ceramic container is made of a non-sticking, temperature change-resistant and solid ceramic. The mechanical movement takes place via a servo-controlled lifting and swiveling device.

The system shows the following advantages:

- Melt pick-up below the bath surface – better melt quality

- Filling of the vessel by suction of the melt - less oxides

- Transfer of the melt without air access – less oxides

- Transfer of the melt in a closed ceramic container - low temperature drop

- High dosing accuracy thanks to integrated, exact quantity recording

- Energy-efficient melting and dosing for the highest alloy qualities

Technical data

AVDF-CM - Aluminium Vacuum Melt and Dosing Furnace

| AVDF-CM | usable crucible contents [kg] | melting capacity [kgAL/h] * | heating capacity [kW] | recommended dosing system sizes |

|---|---|---|---|---|

| 500 | 160 | 200 | 86 | VDU1000 - VDU3000 |

| 800 | 260 | 250 | 115 | VDU3000 - VDU5000 |

| 1400 | 460 | 300 | 155 | VDU5000 - VDU10K |

| VDU | recommended dosing amounts [g] | dosing accuracy [g] * |

|---|---|---|

| 1000 | 100 - 1000 | ± 10 |

| 2500 | 750 - 2500 | ± 15 |

| 3000 | 900 - 3000 | ± 15 |

| 5000 | 1500 - 5000 | ± 25 |

| 10k | 4000 - 10000 | ± 35 |